Ultraviolet light, or UV for short, has an irreversible aging effect on plastics. Therefore, for outdoor connectors, UV resistance determines its quality and durability.

how to choose anti-UV connectors?

For connectors that are often exposed to outdoor environments, especially those with all-plastic housings, they are subject to UV radiation and a series of problems. There are two main aspects:

① Aging

Ultraviolet light can cause the molecular chain in the plastic to break, oxidation, cracking, etc., so that the surface of the plastic material cracking, brittle and other aging phenomena, reducing the physical properties and service life of the plastic.

② discoloration

Ultraviolet light will lead to some additives in the plastic surface or chemical changes in the composition, so that the plastic discoloration, surface gloss reduced, affecting the appearance of quality.

2, how to prevent UV?

① UV-resistant plastic connectors

Select plastic materials with good UV resistance, such as UV stabilizers improved plastic (such as polypropylene, polyethylene, etc.), or after the surface coating treatment, add antioxidants.

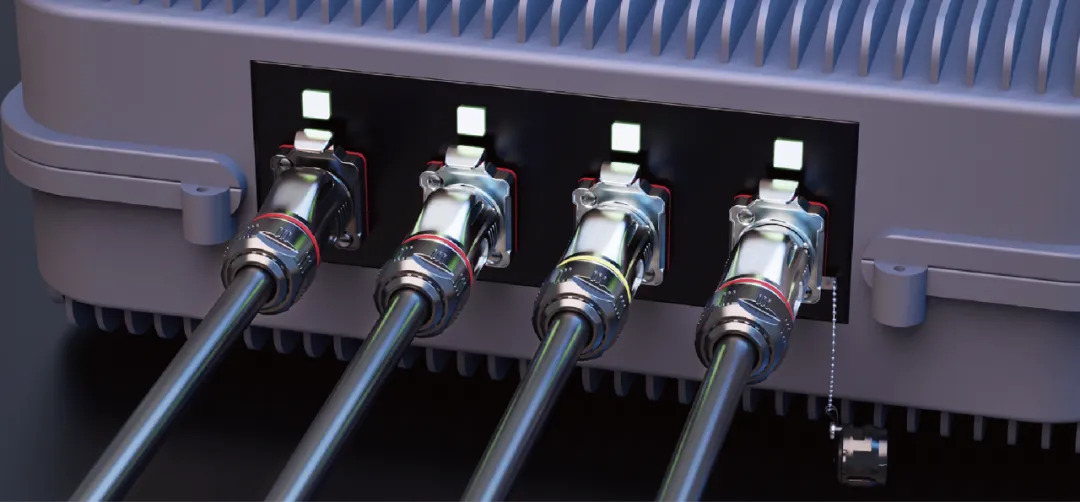

②Connector with metal shell

Choose metal materials with excellent weather resistance (such as stainless steel, alloys, etc.), the free electrons of metal materials do not undergo energy leaps or bond dissociation after absorbing photon energy, so metal materials are almost completely unaffected by ultraviolet rays.

anti-UV BD series

1、Plastic model: f1 grade high performance outdoor engineering plastic, with excellent weather resistance and long-term UV resistance;

2、Metal model: made of high-quality alloy material, with stronger stability, not affected by UV rays;

3、Products through the anti-UV related experimental testing, in line with the standard requirements.

CNLINKO BD series connectors, both plastic shell, or metal shell, have very excellent anti-UV performance. In outdoor environments where UV exposure is severe, the connectors are more durable and reliable.

BD series industrial grade connectors for the German red dot design award and "Shenzhen enterprise innovation record" award a masterpiece. It adopts the original streamlined body and hollow arc back top combined with the appearance of the design, can be said to be the industry's very groundbreaking forward-looking innovation, the real realization of industrial products and the perfect fusion of artistic aesthetics. Of course, in addition to excellent UV resistance, BD series in IP68 waterproof, corrosion resistance, high and low temperature resistance, vibration and impact resistance is also good.

Product features cover power, signal (PIN pin class, RJ45, fiber optic) and data (USB2.0, USB3.0, HDMI) and other connections to meet different scenarios of different devices on the connection of multiple technical requirements.

One of the recommended industry: landscape lighting

Landscape lighting, an important facility to optimize the city's image. For landscape lighting, its power supply and the state control of light on and off, you need to use power connectors and signal connectors to provide power and signal input connections. Due to outdoor exposure, there are more stringent requirements for UV resistance of the connectors.

CNLINKO BD series 3-pin power connectors and RJ45 signal connectors have a very strong UV resistance, can be in the outdoor ultraviolet radiation in the long-term state to protect the connector from aging, fading and other phenomena, achieving a reliable and safe connection.

About CNLINKO

CNLINKO Electric is a national high-tech enterprise and a national "small giant" enterprise specializing in industrial connector research, development and production, insisting on original research and development and independent branding, and its products are well received by users in more than 170 countries and regions around the world.

As one of the drafters of the industry standard, CNLINKO has participated in the drafting of the standard of "High Voltage Shore Connection System (HVSC System) Plugs, Sockets and Marine Couplers Part 1: General Requirements", which belongs to the standard of the marine industry, and has strict requirements for waterproofing.