Flame retardant performance refers to the ability of a material to resist and prevent the spread of flames. So what are the indicators for evaluating the flame retardant performance of a connector? How can stronger flame retardancy be achieved?

What are the indicators for evaluating the flame retardant performance of connectors?

01. How are flame retardant grades classified?

To evaluate the flame retardant performance of plastic connectors, the indicator is the flame retardant grade. There are four levels, gradually increasing from HB, V2, V1 to V0. That is to say, V0 is the highest flame retardant level in the UL94 standard. For metal shell connectors, their flame retardant ability is generally stronger than plastic products.

02. Methods to ensure the flame retardant performance of connectors

1. Choose more flame retardant materials, such as high-temperature plastics and metal materials containing flame retardant additives;

2. Strong adaptability to harsh environments: connectors must be able to adapt to harsh environments such as high temperature, high humidity, or corrosive gases to ensure that the casing is not damaged and the flame retardant ability is not affected;

3. Compliant with flame retardant standards: Ensure that connectors comply with relevant flame retardant standards and certification requirements.

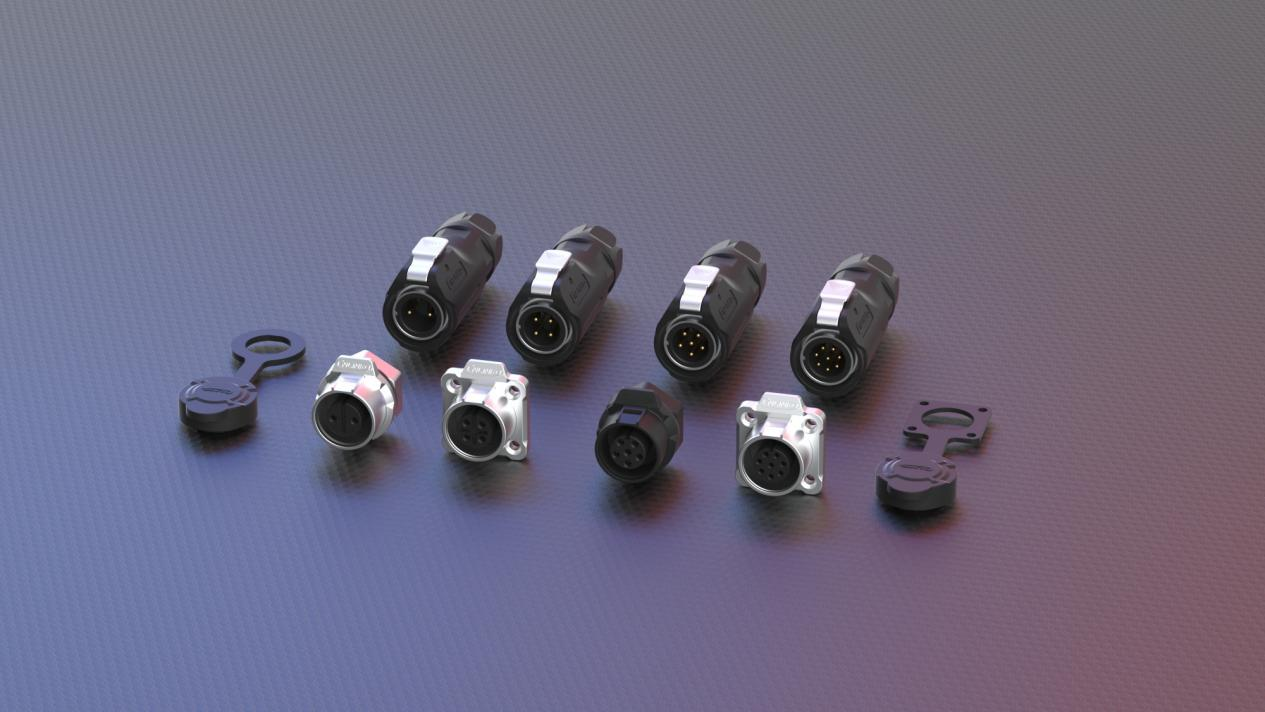

Recommended product LP series: high flame retardant and safer

The flame retardant rating of CNLINKO's LP series connector plastic is UL-94 V0, which is the highest level among existing plastic flame retardant standards, and its flame retardant performance is very strong; The LP series metal version adopts an alloy shell, which naturally has stronger flame retardant ability. Both plastic and metal models have passed professional flame retardant testing certification, fully meeting flame retardant safety requirements and meeting the flame retardant technology requirements in industrial and other scenarios.

One of the recommended industries: fire trucks

Fire trucks have distribution boxes to provide power for onboard equipment and systems. Due to their frequent presence in fire rescue sites, their connectors are mostly industrial. In addition to waterproof and anti-corrosion requirements, special attention is paid to the flame retardant performance of connectors.

The LP series connectors mentioned above by CNLINKO have high flame retardancy. Both plastic and metal models can provide safer fire protection technology in the usage scenarios of fire trucks.